Aluminium Part Sunt essentialia components in numerosis industries, offering herble diuturnitatem et optimum corrosio resistentia. Hoc comprehensive dux explorat omnia vos postulo scio circa aluminium metallum strictis, de vestibulum processus ad realis-mundus applications.

Quid Aluminium Stamping partes?

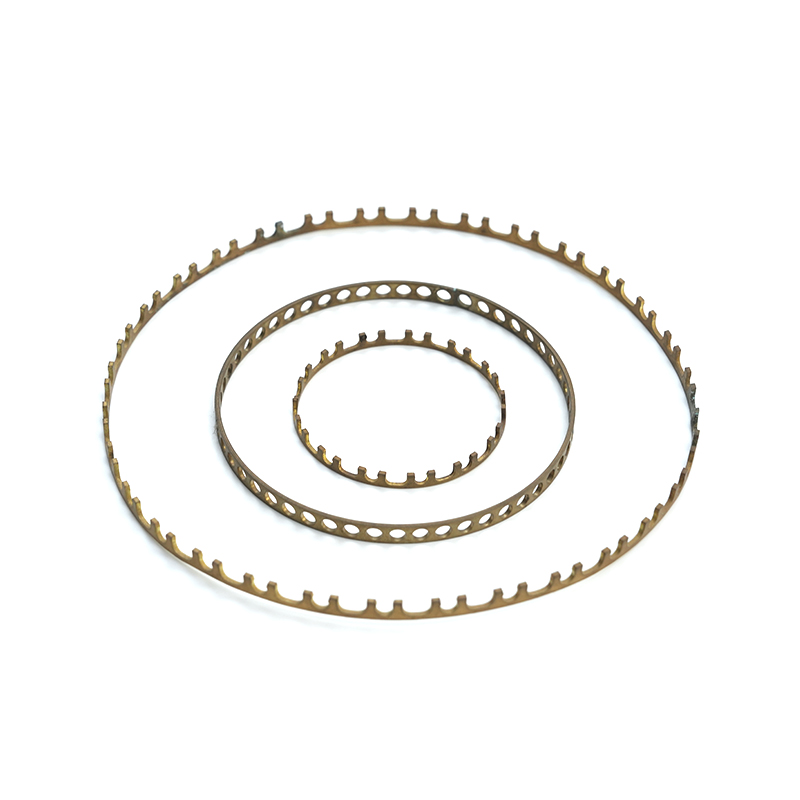

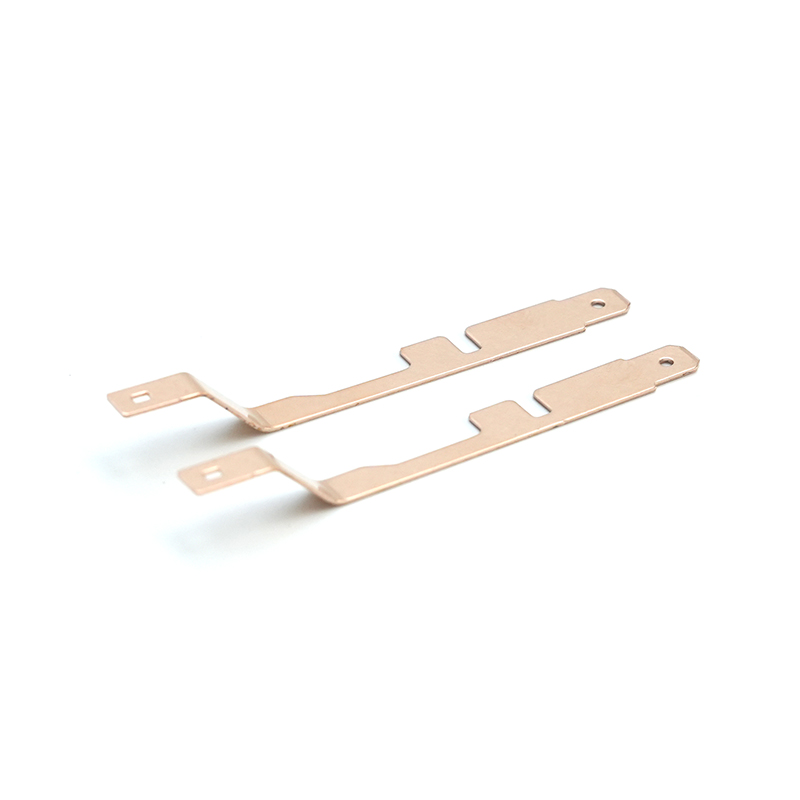

Aluminium Stamping refers to the metalworking processus ubi aluminium laminas vel fiunt formatae in specifica figuras per stamping premit et praecisione moritur. Haec components sunt late in Books, Aerospace, electronics, et dolor bona industries ex Aluminium scriptor unique proprietatibus.

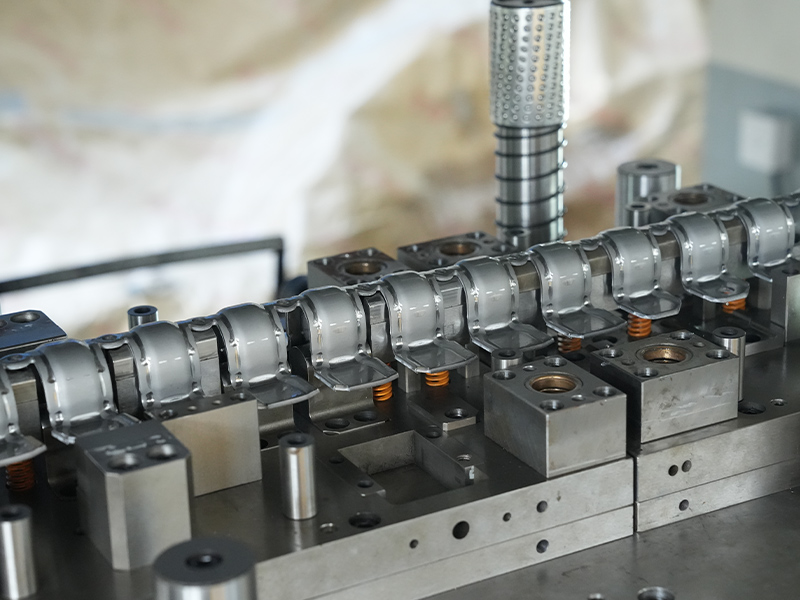

Aluminium Stamping processus Overview

Et Aluminium Stamping vestibulum Processus typically involves his clavis gradus:

- Material Electio: Eligens ius Aluminium Alloy (MC, MMMIII, (V) LII, (VI) LXI, etc)

- Blanking: Secans aluminium sheet in minor pieces

- Formatam: Effingens aluminium per perit et premit

- Piercing: Partum foramina aut cutouts in materia

- Tendentes: Formatam angulos et complexu geometries

- Consummatione: Secundum superficies treatments si requiratur

Commune Aluminium Grades pro Stamping

| Aluminium gradu | Characteres | Typical applications |

|---|---|---|

| 1100 | Optimus formability, princeps scelerisque conductivity | Calor dehersyns, CREPULCUS |

| 3003 | Bonum vires, optimum rorum resistentia | Exornantur Trim, cibus obterere |

| 5052 | Summi viribus non-calor treatable alloys | Marine components, electronic chassis |

| 6061 | Calor Treatable, bonum mechanica proprietatibus | Aerospace partes, structural components |

Key advantages Aluminium Stamping partes

Aluminium Stamping offert numerosis beneficia quae faciunt potior aliis metallum formatam modos:

PROFUSUS proprietatibus

Aluminium est de uno-tertia pondere ferro, faciens fabricata aluminium partibus idealis pondus-sensitivo applications sicut automotive et aerospace components ubi reducendo massa amplio cibus efficientiam.

Corrosio resistentia

Aluminium naturaliter format a tutela cadmiae layer, providemus optimum corrosio resistentia sine postulantes additional coatings in multas environments.

Princeps viribus ad-pondus ratio

Quidam Aluminium Alloys offerre vires comparari aliquando steels dum maintaining significant pondus commoda.

Optimum scelerisque conductivity

Aluminium scriptor scelerisque proprietatibus facere idealis ad calor submersa components et aliis scelerisque administratione applications.

Sumptus-effective productio

Stamping concedit in summus volumine productionem aluminium partibus cum minima materia vastum et efficientem vestibulum cycles.

Design flexibilitate

Aluminium Stamping accommodates universa geometries et precise tolerances, enabling innovative parte consilia.

Applications de Aluminium Stamping partes

Aluminium Stamped Components Servite Critical More Mors per diverse industrias:

Automotive industria

Moderni vehicles incorporate centum aluminium stricta partes comprehendo:

- Radiator components

- Transmissus partes

- Uncis et jactu aggeris

- Electrica connectors

- Corpus Panel et Trim

Aerospace Applications

Aerospace Sector innititur in praecisione Aluminium Stamp est:

- Aircraft structural components

- Avionics inclusis

- Sedes tabulas

- Dolor components

Electronics et electrica

Aluminium Stamping producit essential electronic components ut:

- Calor

- SCELERATIO

- Iungo Housings

- Altilium components

Consumer bona

Quotidie products continet aluminium stricta partes includit:

- Components appliance

- Cookware

- Supellectilem hardware

- Exornantur cultos

Design Considerations Aluminium Stamping

Felix Aluminium Stamping Projects requirere diligenter operam pluribus consilium factors:

Material crassitudine lectio

Eligentes convenientem aluminium crassitudine impingit utraque parte vires et manufacturability. Tenuaner Gauges patitur pro magis universa formatam sed non indigentiam requiritur rigiditate.

Flectere radii guidelines

Aluminium typically requirit maior flectere radii quam ferro ne fregisset. Minimum flectit radium pendeat in specifica mixta et ingenium.

Tolerantia requisitis

Constituendum realis tolerances ensures manufacturabilitatem dum occurrens eget elit. Arctius tolerances augmentum tolerandi costs et ut requirere secundarium operationes.

Superficiem Perago Specifications

Determinare utrum signatur pars requirit speciali superficies treatments sicut anodizing, pictura, vel pulveris coating ad aesthetic vel functional proposita.

Communi challenges in Aluminium Stamping

Dum Aluminium praebet multa commoda, artifices oportet address quaedam provocationes:

Springack effectum

Aluminium scriptor elastica proprietatibus causa formatae partes ad partem redire ad originale figura postquam, requiring ultricies in tool consilio.

Planta et haerentem

Aluminium scriptor mollitiem potest causare materiam adhaero ad moritur, necessitating propriis lubricatae et tool superficiem treatments.

CREPITUS

Improper blanking vel formatam potest ad extremum fracturae, praesertim cum aluminium Alloys et temperat.

Qualis imperium in Aluminium Stamping

Suspendisse consistent qualis requirit multiple verificationem modi:

- Primo, articuli inspectionem

- Dimensional verificationem

- Material Certification

- Superficies metam iudicium

- Eget temptationis

Custus Factors in Aluminium Stamping

Plures variables influere sumptus aluminium tabula;

Material costs

Aluminium prices fluctuare secundum foro conditiones et stagnum cubits. Premium Alloys imperium altius prices.

Tooling investment

Stamping moritur repraesentant significant upfront costs sed facti frugi ad altiorem productio voluminibus.

Productio volumen

Altioribus plerumque reducere per-unitas sumptibus per amortization de tooling et setup expensis.

Secundarium operationes

Additional processus quasi machining, welding, aut superficies curatio auget altiore parte sumptus.

Future Trends in Aluminium Stamping

Aluminium Stamping industria continues evolve cum pluribus emergentes explicationibus:

Provectus Alloy Development

Novum Aluminium Formulationibus offerre improved Formability habet proprietates ad postulans applications.

Dolor vestibulum integration

Industria 4.0 technologies activo-vicis Cras et optimization de Stamping processus.

Sustineri exercitia

Auxit focus in redivivus et industria-agentibus productio modi reduces environmental ictum.

Conclusio

Aluminium Stamping Partes providere ad optimal compositum de lumine perficientur, diuturnitatem et sumptus-efficaciam pro numerosis industriae applications. Intelligendo materiam proprietatibus vestibulum processus et consilio considerationes, engineers et emptoribus potest informari decisiones, cum specifica aluminium faber components. Sicut technology progreditur, Aluminium Stamping et permanere ludere a vitalis munus in productum progressionem trans Tullius Sectors.