Metallum PREMO sunt essentialia components usus est contra innumerabiles industries, ex automotive ad electronics. Hoc comprehensive dux exponit omne opus est scire de STAMPED metallum components, inter vestibulum processus, materiam lectio, qualitas signa, et practical applications.

Intellectus Metal Stamping Technology

Metal stramping est a frigus-formatam vestibulum processus qui utitur perit et stamping premit transform sheet metallum in specifica figuras. Processus offert plures commoda:

- Princeps productio efficientiam

- Optimum dimensional constantiam

- Sumptus-efficaciam pro massa productio

- Facultatem creare complexu Geometries

- Materia PECULIUM cum minimal perditio

Moderni Stamping technology potest producere partes cum tolerances ut stricta quod ± 0.01 mm pro praecisione applications.

Communi typus de partibus

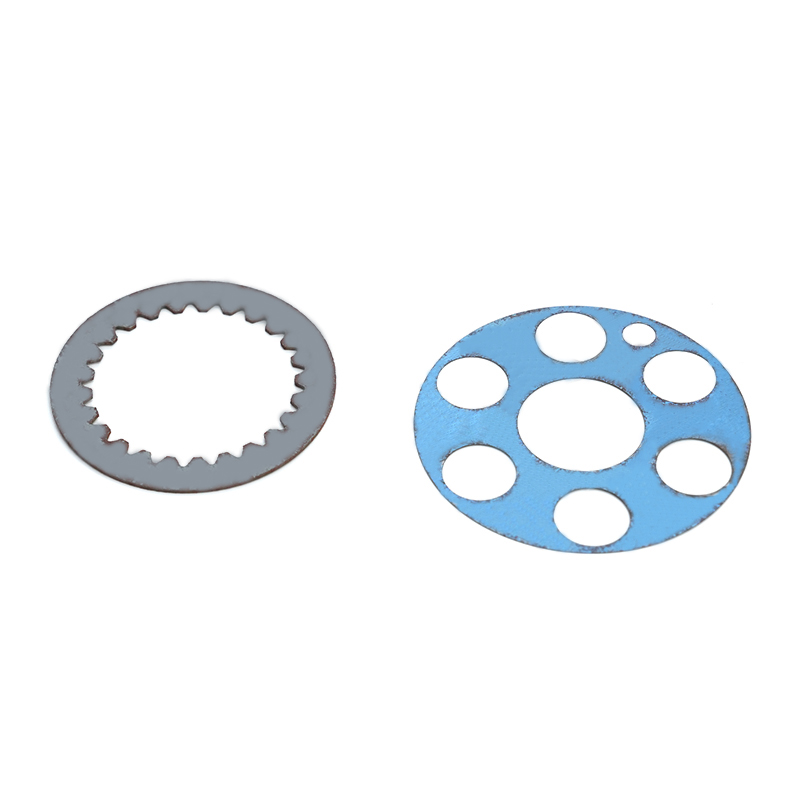

Stamped components potest geno eorum vestibulum processus et finalis forma:

| Genus | Descriptio | Typical applications |

| Blanking partes | Plana components interficiam a sheet metallum | Washers, shims, electrica contactus |

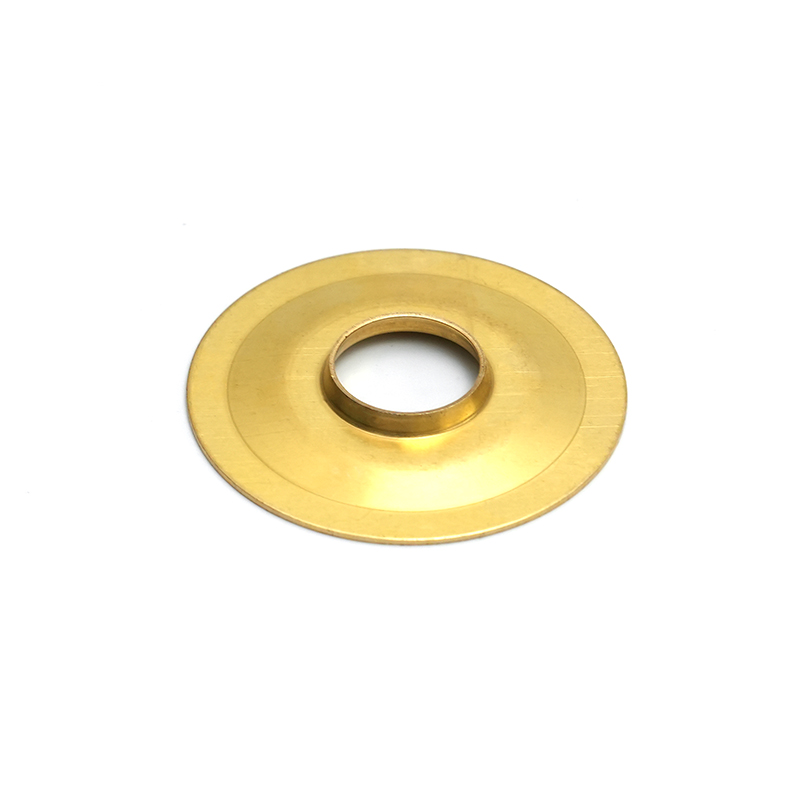

| Tendentes | Components cum angulis vel formatae features | Brackets, clips, Clipsures |

| Partes altum | Tria-dimensiva cavas figuras | Propius, vasis, automotive tabulata |

| Progressive Die | Complexu components in multiple gradibus | Electrical Terminals, Connectors |

| Bysso blanking partes | Summus praecisione components cum lenis marginibus | Gears, Mechanica partibus praecisione |

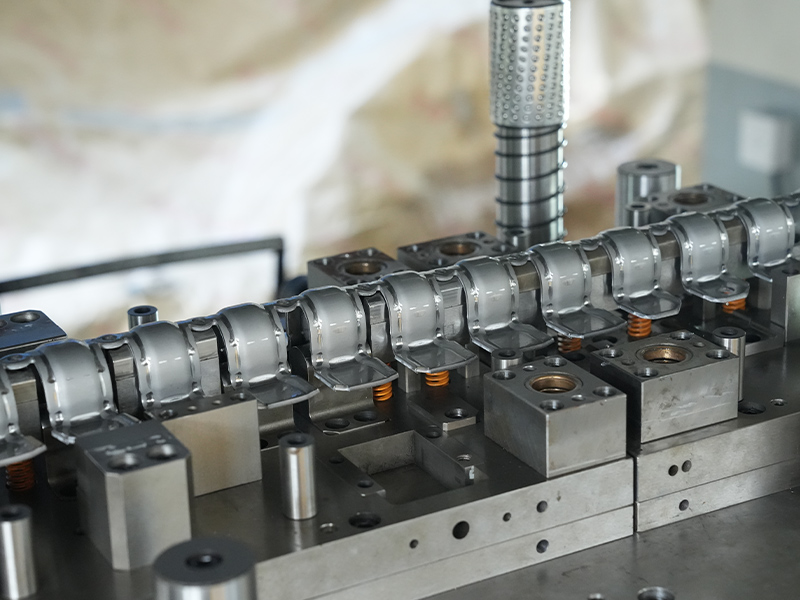

Metal Stamping processum gradum-per-gradus

In metallum, typically involves hos stampam processus,

- Materia Electio: Eligens oportet metallum genus et crassitudine

- Blank Praeparatio: Cutting sheet metallum ad requiratur magnitudine

- Tooling Setup: Installing et aligning perit in torcular

- Stamping Operatio: Formatam partem urgeat

- Secundarium Operations: Additional processus sicut percussoque vel welding

- Qualis inspectionem: Verificare dimensional accurate

- Superficies curatio: Applicando tutela coatings si opus

Popularibus Materials ad partium

Material Electio pendeat ex parte est munus, environmental conditionibus, et sumptus considerations:

| Material | Crassitudine range | Clavem proprietatibus | Communis usus |

| Frigus advolvit ferro | 0.5-3.0 mm | Princeps fortitudinem, bonum formability | Automotive, adjumenta |

| Immaculatam ferro | 0.2-6.0 mm | Corrosio resistentia | Medical, cibum processus |

| Alluminium Alloys | 0.3-5.0 mm | Lightweight, PROLIXUS | Aerospace, electronics |

| Aeris / aes | 0.1-3.0 mm | Optimum conductivity | Electrical components |

| Summus ipsum ferro | 1.0-8.0 mm | Eximia | Machinery industriae |

Critical qualitas imperium mensuras

Utrumque STAMPED pars qualis requirit plures verificationem modi:

- Primo articulus inspectionem: Comprehensive mensura initial exempla

- Dimensional Checks: Using calipers, micrometers et cmms

- Material verificationis: Spectrometer Lorem ad ally compositionem

- Superficies inspectionem: Reprehendo pro scalpit, dents, aut defectus

- Eget Testing: Verbifing fit et perficientur

Statistical Processus Imperium (SPC) modi sunt saepe implemented ad Monitor productio constanty.

Design considerationes pro Stamping partes

Efficens Partite consilio sequitur principiis

- Ponere uniformis murum crassitudine fieri

- Includit oportet flectere radii (typically 1x materia crassitudine)

- Design features ad minimize tool gere

- Considerate frumenti directionem ad flectens operationes

- Patitur pro propriis materia influunt in altum drawing

- Include tolerances oportet ad vestibulum modum

Custus Elementums in Metal Stamping

Plures variables afficit ultima pretium argutissimis components:

| Factor | Impulsum sumptus | Pretium reductionem tips |

| Material Type | 20-60% of totalis sumptus | Alternative Alloys |

| Pars complexionem | Augetur insolens costs | Simpliciorem geometries ubi fieri potest |

| Productio volumen | Superiore voluminibus redigendum unitas sumptus | Miscere ordines cum practica |

| Tolerantia requisitis | Arctius tolerances augmentum pretium | Specificare Looser tolerances ubi gratum |

| Secundarium operationes | Addit Processing Steps | Design ut minimize post-processus |

Industria applications de STAMPED partes

Metal Stamping Serves virtualiter omnis vestibulum sector:

- Automotive: Corpus Panels, uncis, Engine components

- Electronics: Connectiones, protegens, calor demergit

- Medical: Chirurgicam Tools, implantare components

- Adjumenta: Housings, imperium tabulata, cardine

- Construction: Fasteners, hardware, structural components

- Aerospace: Aircraft caerimonias, instrumentation partes

Comparet Stamping ad alternative vestibulum modos

Intelligendo cum eligere Stamping versus aliis processibus:

| Ratio | Commoda | Incomages | Optimum |

| Metal Stamping | Casio, humilis unitas sumptus, praecisione | Maximum tooling sumptus, limitata ad sheet metallum | Missam productionem tenuis components |

| Cnc machining | Flexibile, nec Tooling opus | Tardius, altior per-pars sumptus | Prototypes, complex 3D partes |

| PRAETERIO | Complexu figuris, bonum superficiem metam | Limited ad non-ferrea metalla | Zinc, aluminium components |

| 3D printing | Nullus tooling, Design Freedom | Tardus, materia limitations | Prototypes, Custom partes |

Emergentes trends in stamping technology

Et Stamping Industry continues ad evolve cum novis explicationibus:

- Dolor moritur: Sensoriis pro realis-vicis vigilantia

- Advanced Simulations: Melius praedictio de materia mores

- High-automation: Citius premit cum robotic pertractatio

- Laser-Assisted Stamping: Localized calefactio difficile materiae

- Eco-amica processibus: Reducitur industria et materia vastum

Troubleshooting communi Stamping exitibus

Solutions enim crebris productio problems:

| Problema | Fieri potest | Solutions |

| Burr | Obsidio moritur, improprium alvi | Exacucere / Restituo Dies, adjust alvi |

| CRACKURATIO | Satis flectere radius, iniuriam materiales | Proventus radii, annea materiales |

| Rugis | Satis blank possessor pressura | Adjust pressura, uti ducere beads |

| Springack | Material Memoria Effectus | Overbend, uti ultricies angulis |

| Misalignment | Improprium pascens, fessis ducibus | Reprehendo PASTOR, Restituo Guides |

Sustentationem optimus exercitia pro Stamping moritur

Propriis die sustentationem extenditur tool vitae et ensures qualis:

- Mundus moritur regularly ad removere metallum particulas

- Inspicere ad gere et damnum post se productio currere

- Applicare oportet lubricants ad redigendum friction

- Store moritur bene cum in usu

- Ut detailed sustentationem records

- Agmine operators in propriis tractantem procedendi

Computentur productio requiruntur

Key Formulae pro Stamping Operations:

Press Tonnage Calculation:

Tonnage = (perimeter × Materis crassitudo × Shear Fortis) / MM

Blank magnitudine pro altum drawing:

Blank diameter = √ (ultima pars superficies area × IV / π)

Productio Rate:

Partes / Hour = (MMMDC × Efficens Factor) / Cyclorum Time (seconds)

Environmental considerations

Modicum Stamping Operations Oratio Sustainability per:

- Scrap Metal RecivyCling Programs

- Energy-agentibus servo premit

- Aqua-fundatur lubricants et cleaners

- Perditio reductionem incepta

- Clausa-loop coolant systems

Future Outlook ad Stamping Industry

Metal strato sector proiectum crescere constanter agitata;

- Augendae automotive productio worldwide

- Incrementum in Renewable Energy Infrastructure

- Expansion of Consumer Electronics fora

- Advances in Lightweight Materials

- Integration cum industria 4.0 Technologies

Sicut vestibulum postulat evolve, technology continues ad aptet, offering sumptus-effective solutions ad producendo praecisione metallum components trans diverse industrias.