Quid Ferrum Part ?

Ferro Stamping partes sunt metallum components artificialia per praecisionem Stamp processus quod figuras plana ferrum rudentis in desideravit formas. Hoc sumptus-effective vestibulum modum late in industrias requiring durabile, summus volumine metallum partes cum stricta tolerances. Processus involvit moritur et premit ad Conscidisti, flectere, aut ferrum specifica figuras.

Hi components range ex simplex washers ad universa automotive facis. Frigus-advolvit ferro, galvanized ferrum, et immaculatam ferro sunt communia materiae in Certa processibus. Et versatility ferro stamping facit idoneam variis industriae applications in quo vires et reliability sunt crucial.

Key commoda ferrum Stamping components

Princeps virtutis et diuturnitatem

Ferrum Stricted partibus offerre eximia mechanica proprietatibus quos possidet altum tensile vires et impulsum resistentia. Hoc facit idealis pro Gravis-Officium Industrial Applications Ubi components debet resistere significant accentus et gerunt.

Cost-effective massa productio

Et Stamping processum concedit ad summus volumen productionem cum minimal materia vastum. Cum autem perit sunt creata, manufacturers potest producere millia identical partibus cito, reducendo per-unitas sumptibus significantly comparari machining vel mittens modi.

Praecisione et constantia

Modern PROGRESSUS Techniques potest consequi tolerances intus ± 0.005 pollices, ensuring parte-ut-pars uniformitatem discrimine ad conventu operationes. Hoc gradu praecisione difficile ad par cum alternative vestibulum modos.

Design flexibilitate

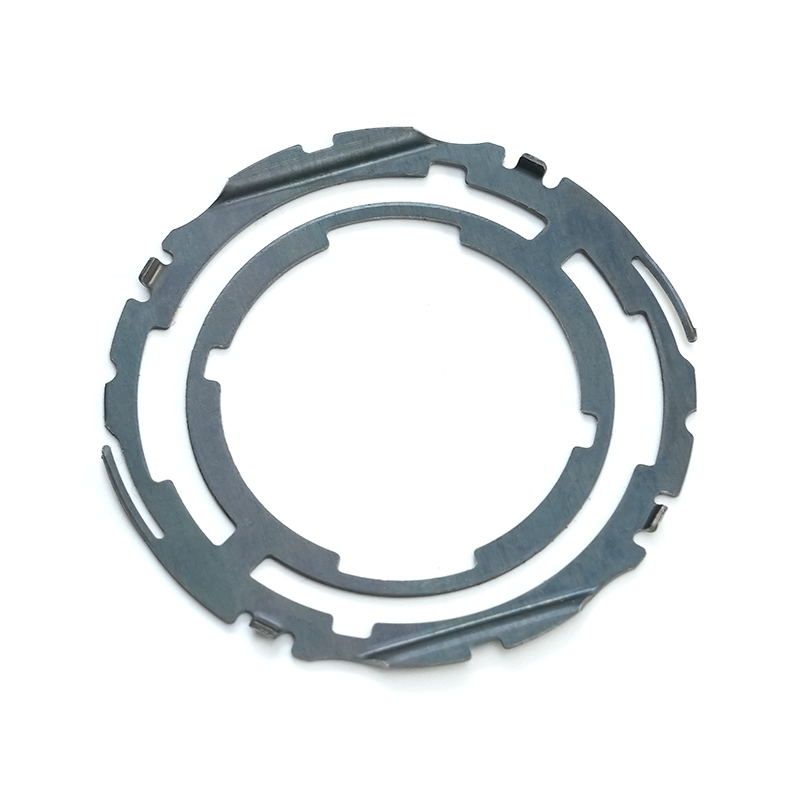

Ferro Stamping accommodates universa geometries inter flectit, flanges, foramina, et caelata features in una operatio. Hoc eliminat multiple machining gradus et simplifies ecclesia processibus.

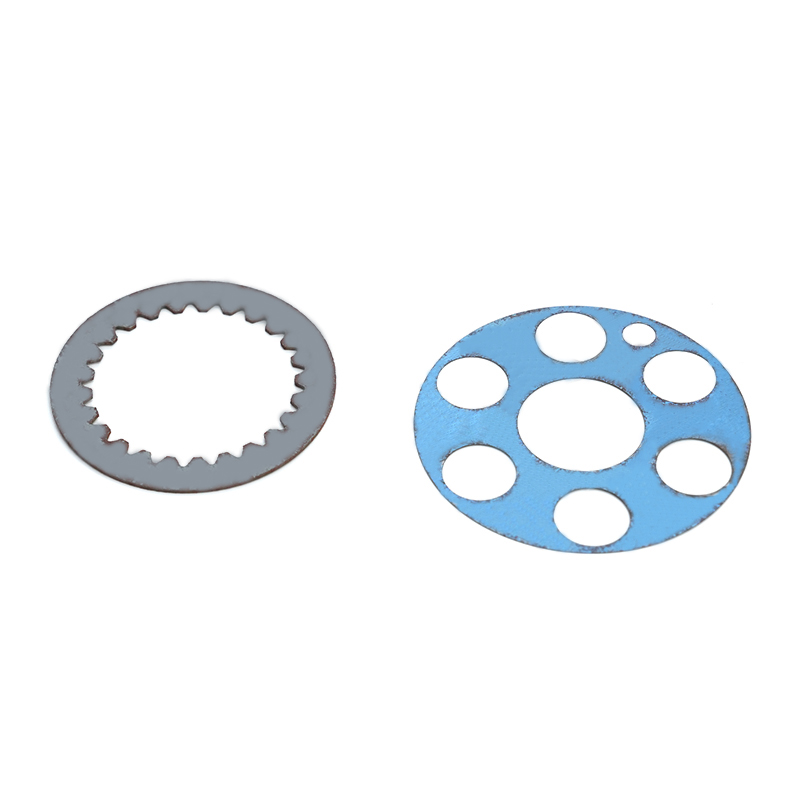

Commune Applications de Ferrum Stricta partes

Automotive components

Et automotive industria extensive utitur Custom ferro Stampings Nam uncis, chassis partibus, engine components et electrica ratio partes. Maximum viribus ad-pondus ratio amplio vehiculum perficientur dum maintaining salutem signa.

Electrical et electronics

TRANSFORMER CORS, motricium laminations et electrica saepius uti praecisione-notatur ferrum partibus debitum ad proprietatibus et diuturnitatem in electrica applications.

Machinery industriae

Gravis apparatu manufacturers confidunt in Dura metallum Stampings Nam Gears, coullings et structural components quod necesse est pati dura operating conditionibus sine defectum.

HVAC Systems

Ductwork, spiracula, et ascendens uncis in calefaciens et refrigerationem systems frequenter incorporate galvanized ferrum Streeting ad corrosio resistentia et structural integritas.

Consumer appliances

Ex baptismata apparatus tympana ad clibano components, ferrum stampings providere necessaria diuturnitatem diu-diuturna appliance perficientur.

Ferro Stamping vestibulum processus

Material Electio

Eligens ius ferrum stomachum est discrimine High-euismod Stampings . Communis Options includit:

- Minimum-Carbon Steel (excellens formability)

- Galvanized ferrum (superior corrosio resistentia)

- Silicon Steel (Electrical Applications)

- Steel immaculatam (hygienic vel exornantur usus)

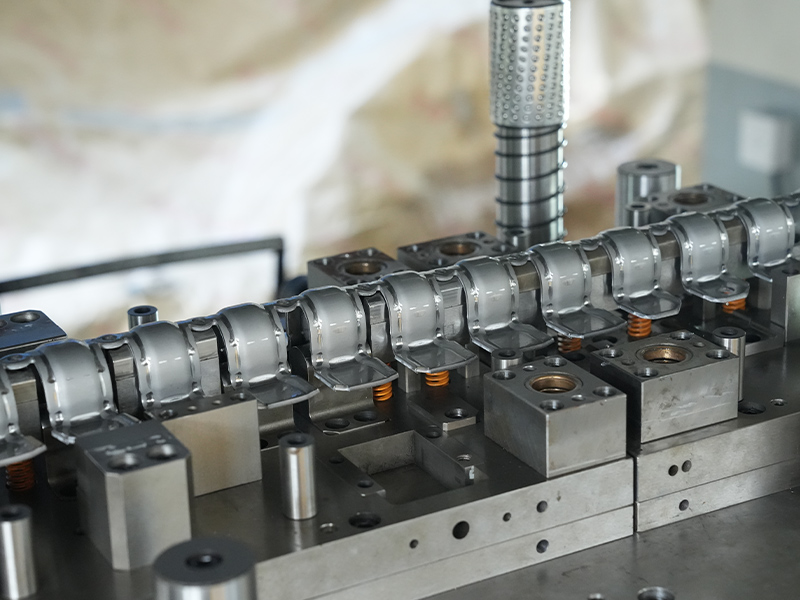

Mors et Design Design

Precisione tooling est disposito usura CAD software et fabricari a induratum instrumentum ferro. Progressive perit potest incorporate plures stationes ad aliquot operationes ordine ut metallum habena pascitur per torcular.

SPIRITUDO

Primarium metallum formatam techniques include:

- Blanking (secans in forma)

- Piercing (creando foraminibus)

- Flectens (formatam angulos)

- Drawing (creando alta formae)

- Coining (High-praecision detailing)

Processes secundarium

Multi ferrum Stampings subit additional treatments:

- Pulveris coating vel pingis ad corrosio praesidium

- Plating auctus conductivity vel species

- Calor curatio ad amplio mechanica proprietatibus

- Deburring ad removendum acri marginibus

Qualis imperium in ferrum Stamping

Repensable manufacturers effectum deducendi stricto Quality Sicutsurance mensuras superiores Per productionem:

Dimensional inspectionem

Coordinare mensuræ machinis (CMM) et optical Comparatores Quin Critica Dimensiones contra Engineering Specifications. Statistical Processus Imperium Tracks variationes super productionem fugit.

Testis materia

Spectrographic Analysis confirmat Alloy compositionem dum obdurare tentationem ensures propriis materia proprietatibus. Tentile probat potest fieri in sample partes.

Superficies species checks

Visual inspectiones et superficiem asperitas mensuras cognoscere metam requisita. Abba Current Testing potest deprehendere subsurface vitiisque in discrimine components.

Eget temptationis

Conventus iudiciis et onus testing convalidandum perficientur per simulatum operating conditionibus ad High-Reliability Stampings .

Eligens in ferrum Stamping elit

Delectos ius manufacturer propter Custom metallum components Requirit diligenter iudicium:

Productio capabilities

Assess torcular Tonnage, maximum pars mole capabilities, et secundarium servitium oblationes. Respice ad usus est similes partes in industria.

Quality certificaciones

ISO (IX) I Certification demonstrat commitment ad qualitas systems. Industria-specifica certificaciones (IATF (XVI) CMXLIX ad Automotive) potest requiri.

Engineering firmamentum

Fortis consilio-pro-manufacturrability peritia potest optimize partes sumptus-effective productio dum occurrens perficientur elit.

Prototyping Services

Celeri prototyping concedit temptationis et elegantiam ante committendo ad productionem tooling. Aestimare plumbum sample partium.

Supply Chain Reliability

Constat materia fontem et productionem facultatem ut on-vicis partus pro vobis Metal Stamping .

Future Trends in ferrum Stamping Technology

Advanced materiae

Development of High-Fortitudo, Lightweight Ferrum Alloys et expand Applications in Automotive et Aerospace dum maintaining structural integritas .

Dolor

IOT-enabled premit cum ipsa-vicis vigilantia mos amplio processus imperium et predictive sustentacionem ad Precision Stamping Operations .

Sustineri exercitia

Auxit usum REDIVIVUS materiae et industria-efficiens processus mos redigendum in environmental impulsum metallum strictis productio.

Hybrid processibus

Combining Stamping cum additive vestibulum aut laser secans erit enable magis universa geometries et eget integration.

Frequenter Interrogata Quaestiones

Quid differentiam inter straming et colanging ferrum?

Stamping operatur cum sheet metallum usura secare et flectens operationes, dum figuras figuras solidum metallum per compressive viribus ad altum temperaturis. Loquitur melius tenuis, complexu partibus cum clangore praebet superior vires ad densissima components.

Quousque non tritici moritur typice tandem?

Qualis instrumentum ferro moritur potest producendum 500,000 ad I decies centena partes vel magis cum propriis sustentationem. Factores afficiens mori vitae includit materia crassitudine, multiplicitate formarum et productionem celeritatem.

Potest ferrum Stampings esse solebat foras?

Galvanized vel bene iactaret ferrum stampings offerre optimum tempestate resistentia. Nam dura environments, immaculatam ferro stampings providere superior corrosio praesidium.

Quid minimam ordinis quantitas pro consuetudine ferro Stampings?

Dum variat per elit, multis manufacturers requirere minimum ordines 10,000 pieces ad consuetam streams to justify tooling costs. Quidam offerimus participatur Tooling options minores decurrit.

Quam accurate sunt ferreus Streent comparari CNC machined partibus?

Modernis praecisione stamping potest consequi tolerances comparabiles ad machining pro multis features (± 0.005 "vel melior), quamquam maxime stricta tolerances potest adhuc requirere secundarium machining operationes.

Conclusio

Ferro Stamping partes manet lapidem angularem ex modern vestibulum, offering optimal statera roboris, praecisione, et sumptus-efficientiam ad altus-volumine productio. Ex Automotive Systems ad Industrial Equipment et Consumer products, haec components libera reliable perficientur trans innumerabiles applications.

As metallum formatam technology Advances, ferrum Stampings et permanere evolving ad occursum magis exposcens specifications dum incorporating sustainable vestibulum exercitia. Intelligendo capabilities et propriis applicationem horum versatile components adjuvat engineers et emptores faciunt certiorem decisiones in propria necessitatibus.

Cum fontem ferrum Stampings, partnering cum periti manufacturer quod offert comprehensive engineering firmamentum et robusti qualitas systems vos accipere components quod occursum tuum exigere requisitis cum optimizing costs.